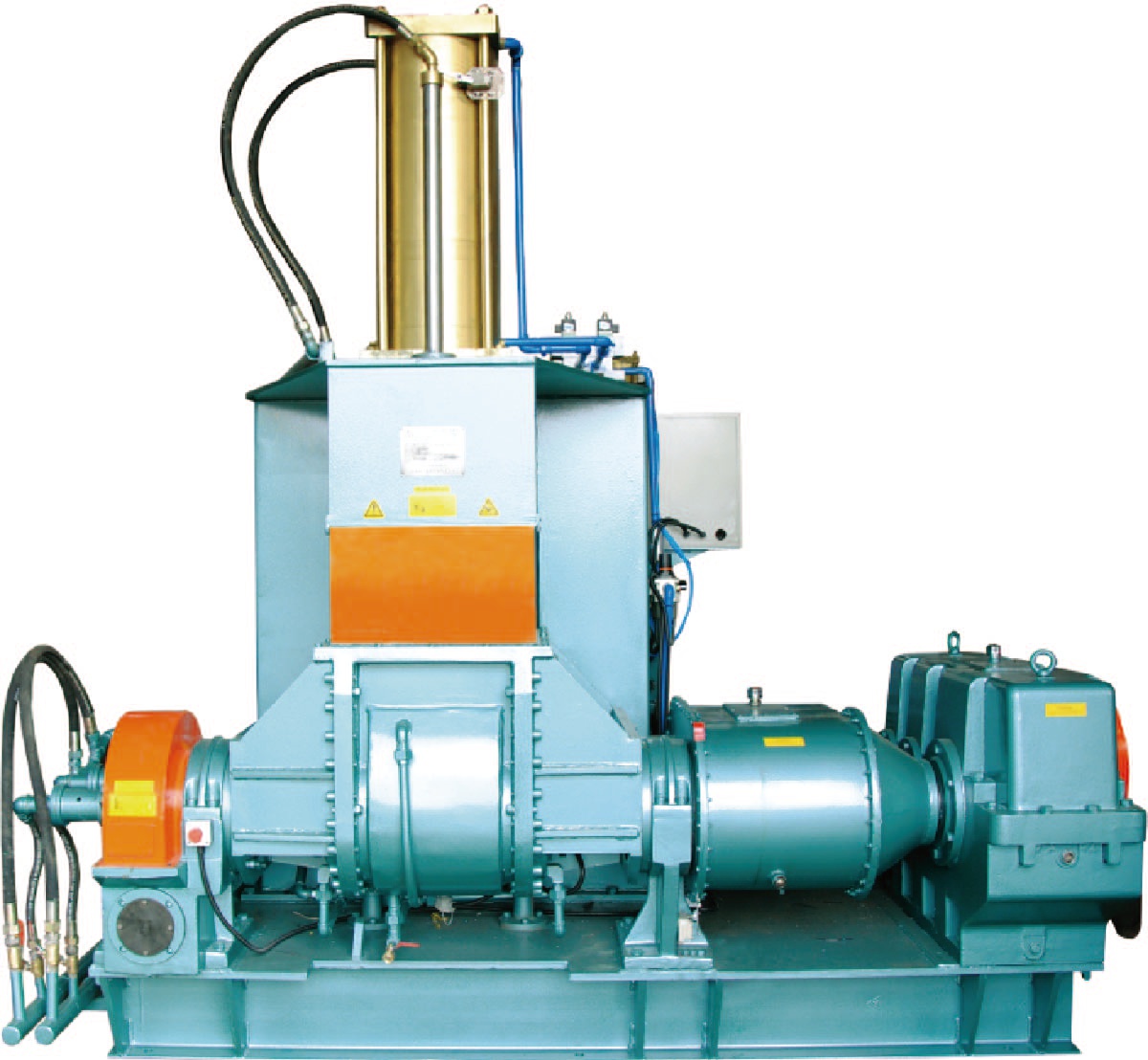

X(S)M Series Rubber(plastics) Internal MixerModel:

Feature:1.The improved shearing and intermeshing rotor could meet most customers’ formula and processing requirements.

2.Shearing-type rotor has two-wings, four-wings six-wings structrue. Intermeshing-type rotor has the wide edge and similar to that of involute meshing area, improve rubber dispersion and cooling effect, guarantee the quality of rubber mixing,

3.All parts, which contact with rubber compound, are circulated through cooling water. This machine may be equipped with water-temperature regulating system to control rubber temperature . Such system adopts suitable water temperature, which can effectively ensure the quality stability of compound.

4.It adopts PLC control system that is featured of meinual and auto control, simple switching, time and temperature control and efficiently controlling the quality of rubber mixing, shortening the support time euid decreeing the labor intensity.

|

Dalian Second Rubber&Plastics Machinery Co.,LTD

0086-0411-87149999

zyh@dalian-exj.com

HQ Add:Liaoning Dalian Guoli Street 286, Beihai Industrial zone, Ganjingzi District

Branch Add:Office in Japan ;Office in India ; Office in Germany ; Office in America .

Factory Add:Guoli Street 286, Beihai Industrial zone, Ganjingzi District

views:52774

Introduction

Full Text

Main Products

-

X(S)N Series rubber (plastics) pressure mixer(kneader)Model:

Feature:1. Under the hermetically closed, pressure and temperature controllable conditions, the rubber/plastics and other accessory ingredients can be successfully kneaded or plasticated with the characteristics of high production efficient, homodispersion of materials, good quality, no contamination to environment, convenience for the processes of material change, color change and cleaning. 2.The turning mechanism adopts the enveloping worm pair (or hydraulic cylinder turnover) 3. These parts can be choose to using hydraulic structure: operation of top ram, material door’s open, side of rotor’s sealing, overturn system of chamber. 4.The materials can be charged from the rear door (or the side) of the machine frame and turn forward the mixing chamber in 140 for discharging the materials and in doing so, it will be either convenient for the linkage of the first and second working procedure of the production flow and clean. -

TPR /EVA/SNF foaming /Hydraulic ram kneaderModel:

Feature:TPR Kneader: Kneading temperature rise quickly, the mixing time is shortt and high efficiency. EVA Kneader: Mixing chamber is forced cooled by the pump circulating water, the material was kneaded at a constant temperature and the material evenly dispersed state. SNF Foaming pressed Kneader: This machine is suited for mixing of high or low ratio expanding for the foaming rubber and plastics. Kneader with hydraulic ram: There is a constant pressure with ram for rubber, can effectively improve the dispersion of various raw materials, increase the quality of mixing rubber (piastic).