The seminar on ultra-low emission treatment technology and key technical equipment of VOCs exhaust gas in rubber factories

Updated:2019-02-26 09:25:22

Date:2018-09-16 - 2018-09-16

Location:Hangzhou

Views:

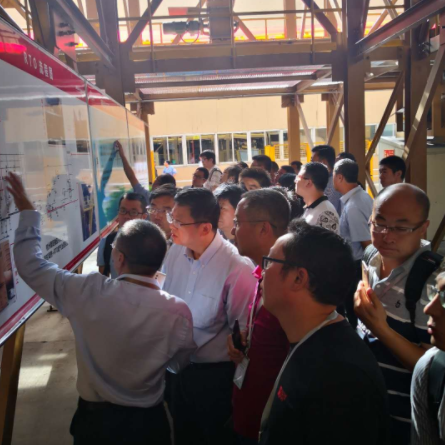

On September 16, 2018, the organizer, National Design&Technology Center of Rubber&Plastics, National Machinery Information Center of Rubber and Plastics, Petroleum Chemical Rubber&Plastics Energy-saving and Environmental Protection Center, and co-organizer, Beijing New Universal Science and Technology Co, Ltd., Hangzhou Chaoyang Rubber Co., Ltd., organized a seminar on ultra-low emission treatment technology and key technical equipment of VOCs exhaust gas in rubber factories was successfully held in Hangzhou.

In order to promote this seminar and the technical application of energy-saving and environmental protection new technologies, new processes and new equipment for rubber factories, the main co-organizers invited more than 80 related enterprises such as tires, rubber products and additives, and nearly 120 industry experts, enterprise leaders and technicians to jointly discuss and promote the upgrading of environmental protection technology in rubber factories.

The meeting was hosted by Ms. Li Qiangqiang, the Secretary General of the National Rubber Machinery Information Center. At the meeting, Mr. Zheng Yusheng, the director of the National Rubber and Plastics Center, gave an opening speech and delivered a speech. Mr. Zhao Caidong, China Federation of Chemical Industry, said: On September 15th, 2018, “The appraisal meeting of ultra-low emission treatment process and key technical equipment of VOCs exhaust gas of rubber plant ” was a complete success! The appraisal experts unanimously agreed that the technology has filled the domestic gap and reached the international advanced level. Subsequently, Ms. Qiangqiang read out the opinions of the appraisal meeting.

It is understood that this technology adopts the integrated treatment technology of pretreatment+secondary filtration+rotary concentrated adsorption+rotary RTO for the first time, which is significantly lower than the emission limit after treatment. The technology is based on the cloud platform of rubber factory RTO exhaust gas control intelligent control system, to achieve management information, intelligent control, intelligent inspection, equipment life management system.

Mr. Zhu Yesheng, Chairman of Beijing New Universal Science and Technology Co, Ltd. said at the meeting, the ultra-low emission treatment technology of VOCs exhausted by New Universal has realized the clean green production of rubber factories, making the environment better, completely changing people's understanding of the tire rubber industry, and the relationship with the surrounding residents is more harmonious. With the continuous development of smart environmental protection technology, New Universal will further play a leading role in the listed companies in the rubber and plastics machinery industry, providing more excellent energy-saving and environmental protection technologies and solutions for the whole industry.

Mr. Li Guijun, consultant of Petroleum Chemical Rubber&Plastics Energy-saving and Environmental Protection Center, introduced the implementation of the national environmental protection and energy conservation policy to promote the energy saving and environmental protection upgrade of the rubber factory. In-depth analysis of the relevant policies of the Ministry of Environmental Protection, and listed the corporate case, analyzed and recommended the VOC governance issues.

Mr. Lou Chaohui, deputy director of equipment department of Hangzhou Chaoyang Rubber Co., Ltd. shared the application of RTO waste gas treatment technology in Zhongce Chaoyang.

The atmosphere of the conference was warm, and the delegates spoke highly of the development of the system equipment, providing solutions for enterprises to find waste gas treatment, and opened up new ways for the green production of the rubber industry.

(R-12)