On April 1, 2019, the chemical industry standard drafted by New Universal Science and Technology, HG/T 5459-2018, "Waste Tire Cracking Carbon Black" has been officially implemented. This is a milestone on the road to standardization of the waste tire cracking industry, pointing out the direction for solving the problem of recycling of waste tires.

The waste tire recycling is a complicated process. If the backward production process and the traditional cracking equipment are used, not only the quality of the pyrolysis carbon black is poor, but it can not meet the requirements of use, and it will cause secondary pollution to the environment. Therefore, the quality and application of cracked carbon black determine the economics of waste tire recycling, and it is also a key link in the recycling and recycling of waste tires.

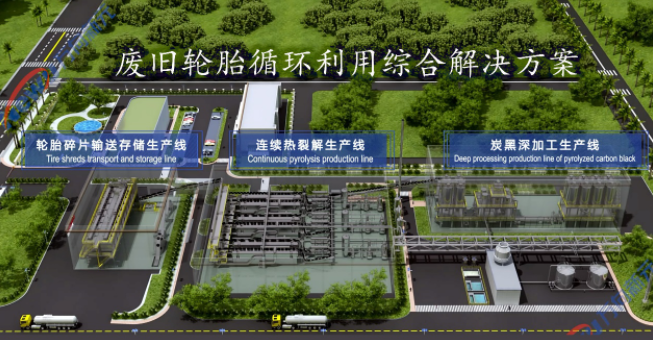

The waste tire recycling project of Beijing New Universal Science and Technology Co., Ltd (referred to as “New Universal Science and Technology”) has broken through the limitations of traditional cracking and refining. Advanced intelligent control system application technology, data intelligent control and production are adopted throughout the line. The self-developed intelligent single-pot multi-layer continuous cracking equipment production is first adopted. The whole process of heating, pyrolysis, carbonization and final pyrolysis temperature is completed in the same pyrolysis kettle. Among them, the solid carbon slag can be completed by the company's self-developed 10,000-ton intelligent equipment, which can complete the whole process of cracking carbon black activation modification, granulation drying and automatic packaging technology. The produced recycled granulated carbon black can replace some commercial carbon black and be used as a rubber reinforcing agent for tire remanufacturing , which formed a virtuous circle of the “waste tires – cracked carbon black – tires” industry chain. The green intelligent cracking equipment and production technology of waste tires can turn "black garbage" into treasure, and the prospect is very broad.

The waste tire recycling is a complicated process. If the backward production process and the traditional cracking equipment are used, not only the quality of the pyrolysis carbon black is poor, but it can not meet the requirements of use, and it will cause secondary pollution to the environment. Therefore, the quality and application of cracked carbon black determine the economics of waste tire recycling, and it is also a key link in the recycling and recycling of waste tires.

The waste tire recycling project of Beijing New Universal Science and Technology Co., Ltd (referred to as “New Universal Science and Technology”) has broken through the limitations of traditional cracking and refining. Advanced intelligent control system application technology, data intelligent control and production are adopted throughout the line. The self-developed intelligent single-pot multi-layer continuous cracking equipment production is first adopted. The whole process of heating, pyrolysis, carbonization and final pyrolysis temperature is completed in the same pyrolysis kettle. Among them, the solid carbon slag can be completed by the company's self-developed 10,000-ton intelligent equipment, which can complete the whole process of cracking carbon black activation modification, granulation drying and automatic packaging technology. The produced recycled granulated carbon black can replace some commercial carbon black and be used as a rubber reinforcing agent for tire remanufacturing , which formed a virtuous circle of the “waste tires – cracked carbon black – tires” industry chain. The green intelligent cracking equipment and production technology of waste tires can turn "black garbage" into treasure, and the prospect is very broad.

The project of "Intelligent Chemical Plant for Green Recycling of Waste Tires" launched by New Universal Science and Technology integrates the self-developed waste tire intelligent equipment and process technology for many years, and applies gas purification and treatment technology, video surveillance and digital management technology, intelligent inspection robot, intelligent manufacturing service and cloud computing platform. The purpose is to contribute to the tire industry to build a smart, environmentally friendly and unmanned waste tire recycling plant.

(R-12)