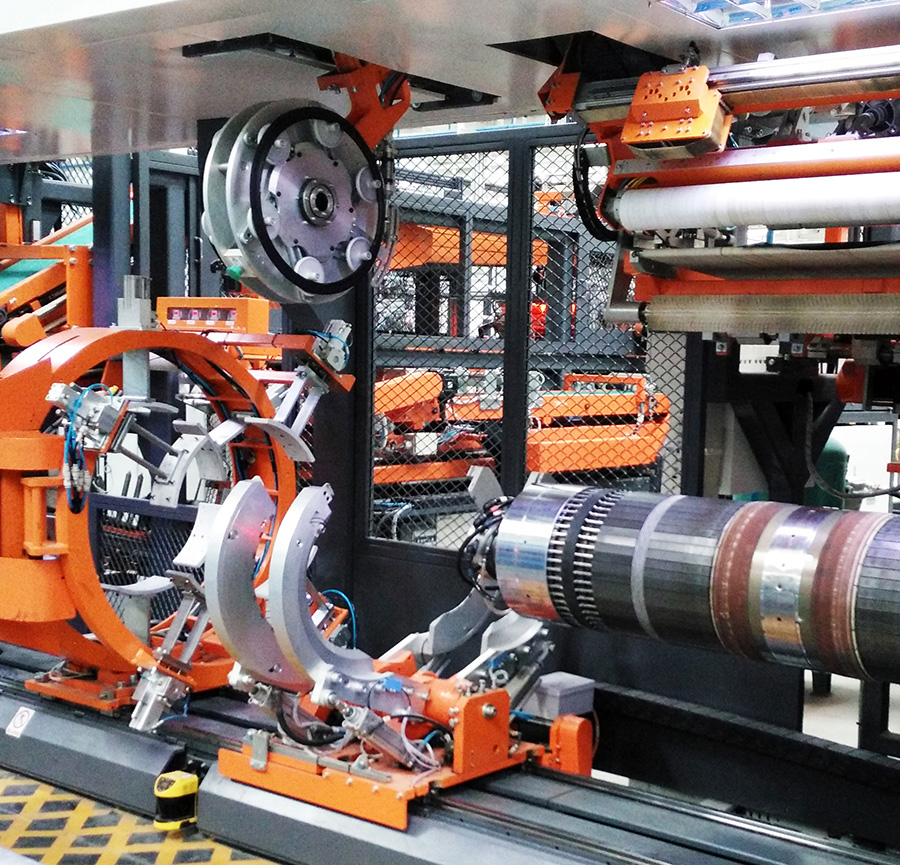

Semi-steel

Characteristic1. The AC servo system and CCD system be equipped to realize the auto length fixing, auto cutting, auto centering, auto splicing of inner liner, sidewall, body ply, belt and tread. So a tire building cycle is optimized within 60 seconds, and the output as 480pcs/shift; 2. The mechanical components processed with high precision have ensured not only the excellent mechanical properties and precision of the whole machine, but also guaranteed the high quality tires produced out; 3. PLC is equipped in whole building process. The human-machine interface screen with the functions of setting process parameters, storing specifications, displaying building process and faults analyzing, it operates easily, and tire specifications change quickly; 4. Using electric magnet, it increases the right & left stop accuracy of transfer ring.