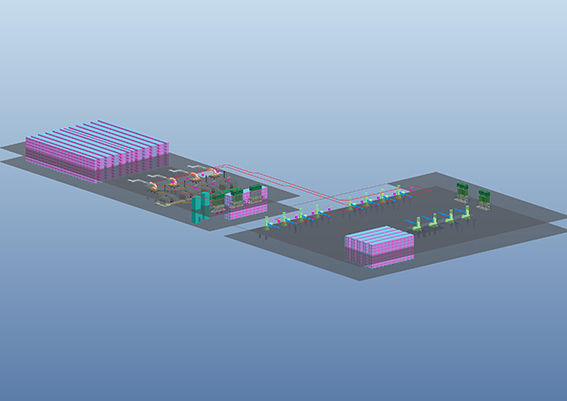

Single step mixing and production lineModel:

Feature:Single Stage Mixing and Production Line, mix master batch in the mixer , then continuously mixing and compounding in mills. It realize whole mixing process from raw material to final batch, automatically and continuously, in one step.

This system can improve quality and productivity of compound at the same time. Long time mixing in mills , raise decentrality of additives and chemicals, increase stability and homogeneity of rubber compound. At the same time , heighten abrasion resistance and rolling resistance performance.

Introduction

Full Text

Main Products

-

Automatic rubber preparation systemModel:

Feature:The advantages of this transport system are as follows: ①This system can be designed and installed according to the requirement of users. And, it makes use of space effectively to reduce the area of workshop. ②This system adopts automatic control, automatic loading and unloading and automatic identification of bins during transport, which is to ensure that there’s no error will be caused by transport bins, and reduce labor intensity with high efficiency and quality. ③The whole process of transport can be monitored real-timely. It is useful for equipment management and finding abnormal situation in time. ④Automatic weighing and automatic transport are realized. Production data can be displayed real-timely and saved automatically, which is convenient for analysis and query in the future. -

Logistics transportation and warehousing systemModel:

Feature:This system is used for automatically transport and Temporary Storage from raw material to products in the tire and rubber industry. To solve the continuous production problems in mixing, extruding and calendaring, building, curing and tire inspecting processes. To realize the automatically transportation and information management. Users can select system according to production needs.