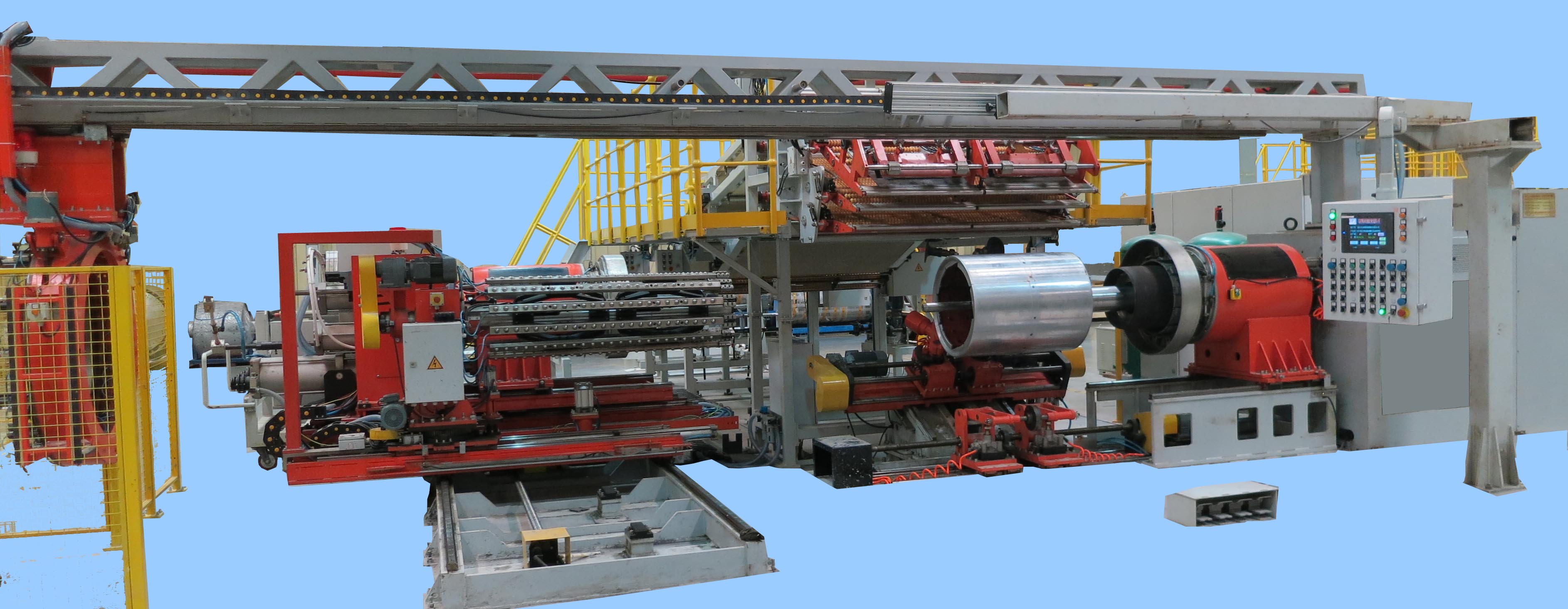

First Stage Aircraft Radial Tyre Building MachineModel:LCHY1823-JY

Feature:1. High accurately processed machine parts ensure the excellent mechanical performances and accuracies of the whole machine and provide the guarantee to produce the high quality green tyres;

2. During whole building process PLC are used,with touch screen type HMI operation used to perform the functions to set process parameters, store sizes, display building process and fault diagnosis etc.,enabled the easy operation and quick and direct change of the size data;

3. The main shaft with frequency converter is used,to satisfy the rotation speed needed when assembling or stitching;

4. The finger turn-down, bladder turn-up and push devices are used to ensure fully the tyre building quality;

5. The turn-down and turn-up devices are supported forward and backward movable on the linear guide rails of the bed plate,ensured the equipment accuracy and thus improved the tyre quality......

Introduction

Full Text

Main Products

-

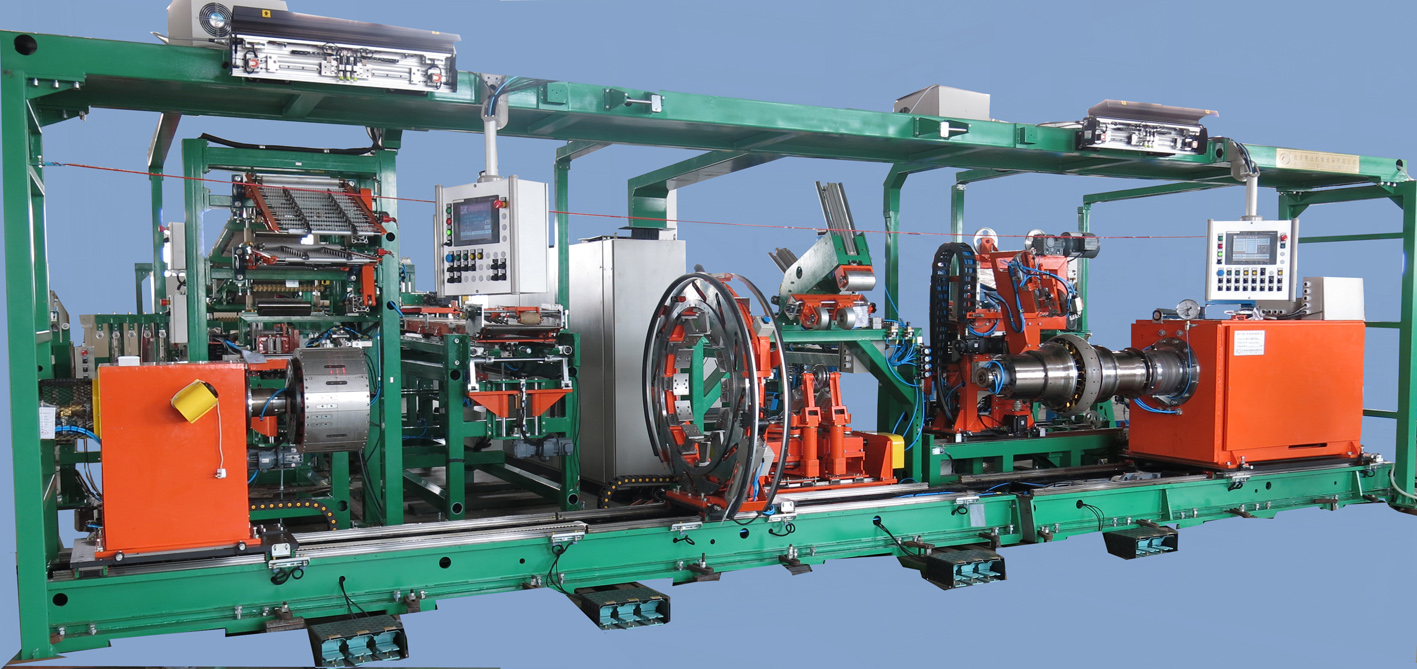

First Stage Motorcycle Radial Tyre Building MachineModel:LCMY1419-JY

Feature:1. The drum is of a radial collapse drum mechanism, which can collapse and expand the drum in working state, with accurate positioning, free of noise, ensured that the drum segments would not collapse, increased the service life of the building drum of the motorcycle tyre building machine; 2. The turn-up and turn-down bladder are used for the turn-up and turn-down process of the band and beads. The bead rings are manually placed over a pair of bead setter rings, which automatically set and assembled. The bead setter rings can be individually changed; 3. The ply servicer includes a total four-tier servicing system for 2plies of body plies, one ply of inner liner and one sidewall; 4. The rear stitcher unit was driven by the cylinder and pressured flexibly by the air spring, The bottom roll stitcher unit was driven by the ball screw through the AC motor and pressured by the cylinder force the stitcher, and it has the function of switch the pressure from high to lower ...... -

Second Stage Motorcycle Radial Tyre Building MachineModel:LCME1619-JY

Feature:1.High accurately processed machine parts ensure the excellent mechanical performances and accuracies of the whole machine; 2.The whole machine is PLC controlled. HMI operation makes the size adjustment and process data change much quicker, much direct and much easier. The functions like real time process monitoring, fault display, diagnosis make the machine operation and maintenance much quicker, much direct and much easier; 3.Belts are manually cut after application on the B&T Drum. It uses the bobbin to feed to guarantee the belt non-stretch and non-distortion during the tyre building; 4.Two sets of tread servicer separate by building side and shaper side,this could be ensure the machine have a high efficiency and meet the different process requirement......