Biological Deodorization SystemModel:

Feature:MESNAC has established a professional microbiological laboratory and R&D team to tackle with this problem and develop deodorization micro-organism, including its selection and cultivation. MESNAC actively conducts experimental research on gases of different components and densities, and independently develops optimized micro-organisms to digest, absorb and transfer harmful substances in the exhaust gases into harmless and odorless inorganics. The after-treatment is fully compliance with national emission standards.

1. Advanced micro-organisms specially-designed for exhaust gas treatment in rubber production, with high efficiency and good deodorizing effect;

2. Simple operation and maintenance, automated control of temperature and humidity;

3. Environmental-friendly design, no secondary pollution;

4. Low energy consumption and operation costs, only need water and electricity in daily operation;

5. Strong micro-organisms, short biofilm time and long lifespan.

Introduction

Full Text

Main Products

-

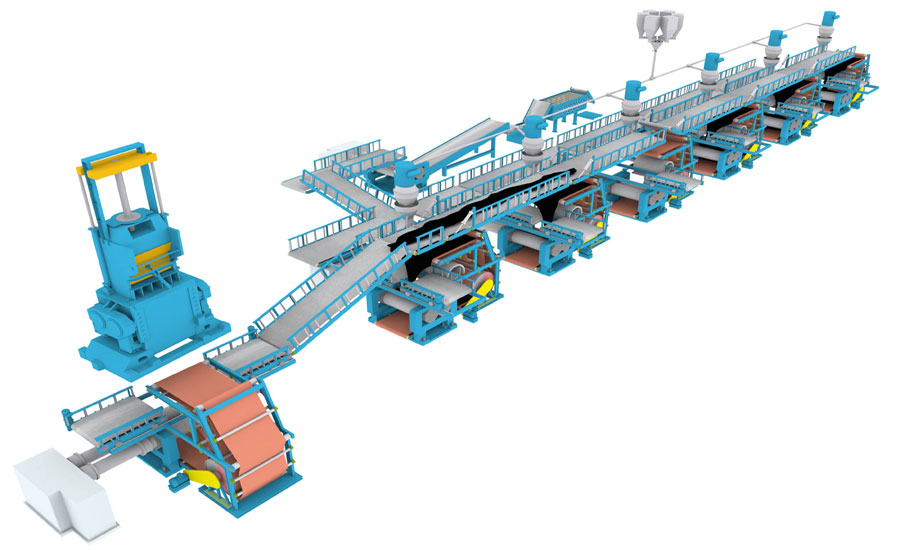

One-Step Mixing SystemModel:

Feature:The system changes traditional multi-stage mixing into unistage type, which saves time, energy and space. It can be special designed for customer according to their productivity. Realizes continuous production, gets final mixed compound for one time, high automation and productivity; Reduces manual operation and decrease labor cost, the rubber quality is stable; Carbon black and ingredients are mixed more evenly, improves rubber tensile strength, abrasion resistance and fatigue resistance Reduces gas pollution, optimizes production environment and realizes green production. -

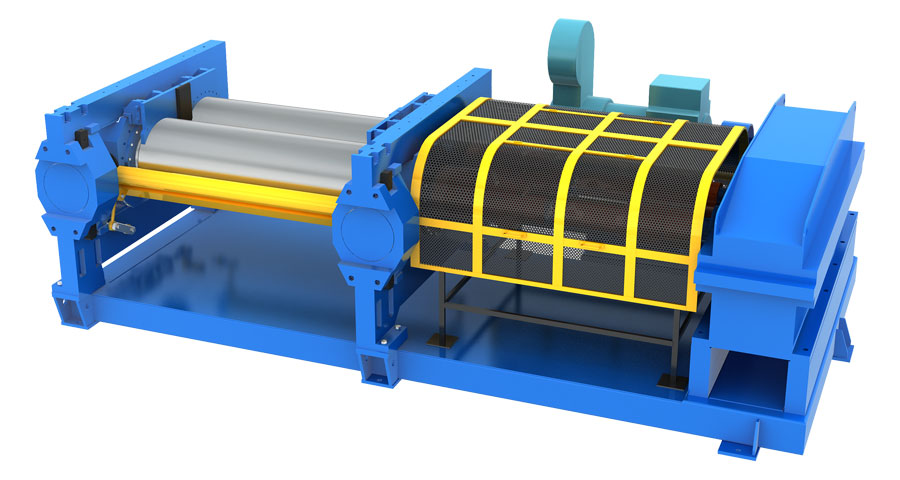

Open millModel:

Feature:Open mill is the essential equipment in rubber mixing, sheeting and feeding. Supported with advanced design concepts, world\'s leading manufacturing technology and eco-friendly & energy saving philosophy, MESNAC launches the new generation open mill, which is safe, energy-saving and simple in operation and maintenance. Adopt centrifugal technique in roller casting, with long lifespan C-frame structure, easy to maintain, good appreance; Compared with traditional models, new open mill saves over two-thirds of covered area; New drive transmission, save energy by one-third.

Patents

Knowhow