Inner-liner Production LineModel:

Feature:It produces different sizes inner-liner for TBR, PCR and OTR, and can be special designed for customers according to their requirements.

All of the three type strips for inner-liner are applied for one time, high productivity, air tightness and density;

The strips are centering and applying at uncooled state, no bubble between strips;

Check and trace strip width and position changing automatically, automatically adjust application position with high application accuracy;

Better designed die head channel, fill evenly and has stable pressure;

Special screw design ensures strip productivity;

Introduction

Full Text

Main Products

-

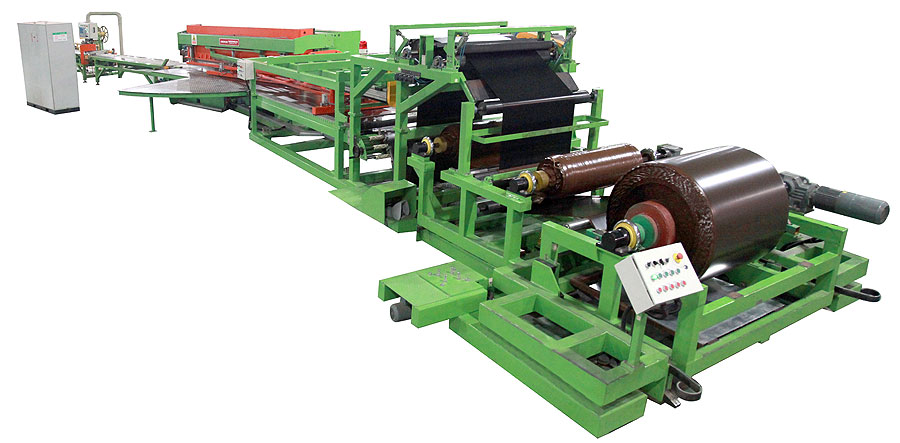

Steel Ply Cutting LineModel:

Feature:With MESNAC many years experience in equipments operation and research and innovation, the new machine has higher accuracy, faster speed and better stability. Software and hardware perfectly matched, high automation, easy operation and the labor cost is reduced; High speed and accuracy of cutting and splicing, high productivity of semi-products, linear vertical cutting can be used to improve output; Numerous edge wrapping types satisfy all kinds of technique requirements; Special mechanical and electrical protection system ensure operator and equipment safety; Flexible customized structure, with double let-off working positions, double windup units; -

Fabric Ply Cutting MachineModel:

Feature:It is used for producing ply with different specifications, with features of high cutting accuracy, precise splicing positioning and high production efficiency. The key components of the production line are controlled efficient, stable operation and high accuracy; Realizes each unit automatic control; Material suction device adopts linear motion module, with high efficiency and long service life; According to customer requirements, to provide personalized products.

Patents

Knowhow